Ceresit Ceretherm

IMPACTUM

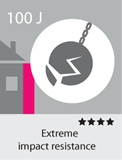

A unique insulation system with exceptional flexibility, strength and impressive impact resistance to over 100 J.

It protects the building like a helmet, ensuring safety even in the most demanding weather conditions and also while at risk of strong mechanical damage.

All these guarantee extreme durability and aesthetics for insulated facade.

Highest impact resistance & durability

CHARACTERISTICS

- extreme durability

- extreme flexibility and impact resistance to mechanical damages (100 J) & weather/ temperature abrupt changes & thermal stresses

- strengthened with carbon, glass and polyacrylamide fibres

- extreme UV resistance

- highly hydrophobic (deep structural hydrophobisation)

- extremely low water uptake of the system

- high resistance to biological contamination (structure & structural hydrophobicity)

- self cleaning & dirt resistant

- excellent working parameters

- quick & convenient in installation ( rendering mortar R2U – no priming paint)

- possible use of dark and intense colours (HBW‡ 5%) on facades

Recommended substrates: aerated concrete (dry) well ventilated building, concrete, ceramic bricks and ceramic blocks

Recommended buildings: single family houses, blocks of flats up to 11 floors (up to 25 m) and public buildings

Especially recommended for: buildings located in areas with high temperatures differences, tough weather conditions and strong UV exposure, buildings located in high air humidity areas and buildings located in air polluted areas (close to roads, industrial areas)

Strongly recommended for: socles, fronts of buildings and entrances

SPECIFICATION

| 1. Fixing |

|

| 2. Insulation material | EPS-boards marked Ceresit CT 315 (or others classified as PN-EN 13163:2004) with thickness up to 25 cm, with a flat or shaped end face |

| 3. Reinforced layer |

|

| 4. Priming paint | not necessary |

| 5. Plaster |

recommended: Elastomeric Plaster: Ceresit CT 79; |

| 6. Paint | Acrylic Paints: Ceresit CT 42, Ceresit CT 44; Silicone Paint: Ceresit CT 48; Silicate Paint: Ceresit CT 54; Nanosilicone Paint Ceresit CT 49 Silix XD® |